-

Tayfun from Turkeysolar pump inverter is really in very good quality and we also prepared some promotional products for exhibition. We are going to make new orders soon. Last year there was only one local agent and this year, there are more than 8. Some of them only sell Veikong!

Tayfun from Turkeysolar pump inverter is really in very good quality and we also prepared some promotional products for exhibition. We are going to make new orders soon. Last year there was only one local agent and this year, there are more than 8. Some of them only sell Veikong! -

Cristian from ChileIt’s very good! LCD options make it much easier to use. That’s the strong point, easy of use. And robust. Great PC software.

Cristian from ChileIt’s very good! LCD options make it much easier to use. That’s the strong point, easy of use. And robust. Great PC software. -

Brahim assad from SyriaVFD500 output frequency is stable when the others are fluctuating. Also output current is less than others, that’s why output frequency is higher too which can save more energy.

Brahim assad from SyriaVFD500 output frequency is stable when the others are fluctuating. Also output current is less than others, that’s why output frequency is higher too which can save more energy.

| Place of Origin | China |

|---|---|

| Brand Name | VEIKONG |

| Certification | CE |

| Model Number | VFD500-PV |

| Minimum Order Quantity | 1 |

| Price | Negotiable |

| Packaging Details | the power less than 45kw use Carton, starting from 45kw use Wooden case |

| Delivery Time | 3 days, depend on the order quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 15000pcs per Month |

| Product Name | 5.5kw VFD | Voltage | 220v/380v |

|---|---|---|---|

| Type | AC Inverters | Power | 5.5kw/7.5hp |

| Warranty | 18 Months | Igbt | Infineon |

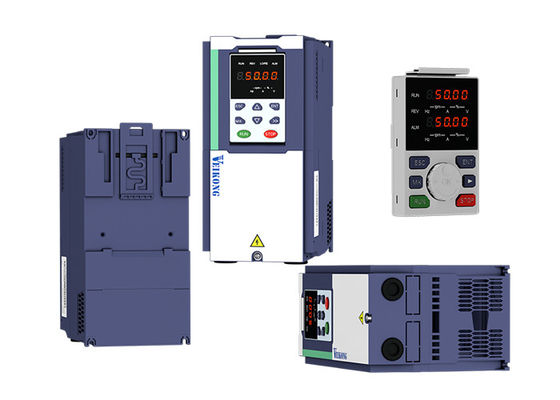

5.5KW vector control VFD for crusher application ac drive inverters

High performance

1. More Accurate Motor Autotuning

2. Advanced open and close loop vector control

3. Perfect voltage and current control, reducing the fault protection times

4 Multiple braking modes and instant stopping

5. 0.75kW~7100kW(Three Phase 400V)

Features

- High-performance vector universal platform, brand new motor control algorithm.

- Synchronous and asynchronous drives are integrated, open loop and closed loop are comprehensive.

- Software and hardware modular design requirements, strong expansion capabilities.

- Rich interface accessories, covering various applications.

- Book design, save installation space.

- Optimize the convenient keyboard design, support the new external keyboard.

- The upper and lower straight ventilation ducts are designed to dissipate heat by DC fans.

- PCB spraying three-proof paint to ensure product stability and reliability.

VFD500 parameter distribution list

| Classification | Parameter group | Page |

| Common parameters | 00:Basic function | Page 30 |

| 01:Frequency source selection | Page 32 | |

| 02:Start and stop | Page 37 | |

| 03:Ramp and S curve | Page 39 | |

| 04: Analog and pulse input | Page 41 | |

| 05:Analog and pulse output | Page 45 | |

| 06: Multi-function Digital input (DI) | Page 46 | |

| 07: Multi-function Digital output(DO) | Page 49 | |

| 08:Digital Output setting | Page 51 | |

| Motor control | 10:Encoder type | Page 53 |

| 11:Motor1 parmeter | Page 54 | |

| 12:Motor1 VFcontrol parameter | Page 56 | |

| 13:Motor1 Vector controlparameter | Page 58 | |

| 14:Torque control | Page 59 | |

| 16:Energy saving control | Page 61 | |

| Display and protection | 20:User-defined parameters | Page 62 |

| 21:Keypad and display | Page 63 | |

| 22:AC Drive configuration | Page 65 | |

| 23:Drive protection function setting | Page 67 | |

| 24:Motor protection parameter | Page 70 | |

| 25:Fault tracking parameter | Page 72 | |

| 26:Fault recording parameter | Page 72 | |

| 27:Monitoring parameter | Page 74 | |

| Communication | 30:Modbus communication | Page 75 |

| Application | 40:Process PID Function | Page 77 |

| 41:Sleep function | Page 81 | |

| 42:Simple PLC | Page 82 | |

| 43:Programmable delay unit | Page 84 | |

| 44:Comparator and logic unit/controller | Page 86 | |

| 45:Multifunction counter | Page 90 | |

| Motor 2 | 60:Motor2 basic parameter | Page 91 |

| 61:Motor2 parameter | Page 91 | |

| 62:Motor2 VF control parameter | Page 92 | |

| 63:Motor2 vector control parameter | Page 92 |

Techincal Parameters:

| Item | Specifiation | |

| Input | Inuput Voltage |

1phase/3phase 220V:200V~240V 3 phase 380V-480V:380V~480V |

| Allowed Voltage fluctuation range | -15%~10% | |

| Input frequency | 50Hz / 60Hz,fluctuation less than 5% | |

| Output | Output Voltage | 3phase:0~input voltage |

| Overload capacity |

General purpose application:60S for 150% of the rated current Light load application:60S for 120% of the rated current |

|

| Control | Control mode |

V/f control Sensorless flux vector control without PG card(SVC) Sensor speed flux vector control with PG card (VC) |

| Operating mode | Speed control,Torque control(SVC and VC) | |

| Speed range |

1:100 (V/f) 1:200( SVC) 1:1000 (VC) |

|

| Speed control accuracy |

±0.5% (V/f) ±0.2% (SVC) ±0.02% (VC) |

|

| Speed response |

5Hz(V/f) 20Hz(SVC) 50Hz(VC) |

|

| frequency range |

0.00~600.00Hz(V/f) 0.00~200.00Hz(SVC) 0.00~400.00Hz(VC) |

|

| Input frequency resolution |

Digital setting: 0.01 Hz Analog setting: maximum frequency x 0.1% |

|

| Startup torque |

150%/0.5Hz(V/f) 180%/0.25Hz(SVC) 200%/0Hz(VC) |

|

| Torque control accuracy |

SVC:within 5Hz10%,above 5Hz5% VC:3.0% |

|

| V/f curve |

V / f curve type: straight line, multipoint, power function, V / f separation; Torque boost support: Automatic torque boost (factory setting), manual torque boost |

|

| Frequency giving ramp |

Support linear and S curve acceleration and deceleration; 4 groups of acceleration and deceleration time, setting range 0.00s ~ 60000s |

|

| DC bus voltage control |

Overvoltage stall control: limit the power generation of the motor by adjusting the output frequency to avoid skipping the voltage fault;

Undervoltage stall control: control the power consumption of the motor by adjusting the output frequency to avoid yaw failure

VdcMax Control: Limit the amount of power generated by the motor by adjusting the output frequency to avoid over-voltage trip; VdcMin control: Control the power consumption of the motor by adjusting the output frequency, to avoid jump undervoltage fault |

|

| Carrier frequency | 1kHz~12kHz(Varies depending on the type) | |

| Startup method | Direct start (can be superimposed DC brake); speed tracking start | |

| Stop method | Deceleration stop (can be superimposed DC braking); free to stop | |

| Maincontrol function | Jog control, droop control, up to 16-speed operation, dangerous speed avoidance, swing frequency operation, acceleration and deceleration time switching, VF separation, over excitation braking, process PID control, sleep and wake-up function, built-in simple PLC logic, virtual Input and output terminals, built-in delay unit, built-in comparison unit and logic unit, parameter backup and recovery, perfect fault record,fault reset, two groups of motor parameters free switching, software swap output wiring, terminals UP / DOWN | |

VEIKONG VFD replace famous brand VFD

![]()